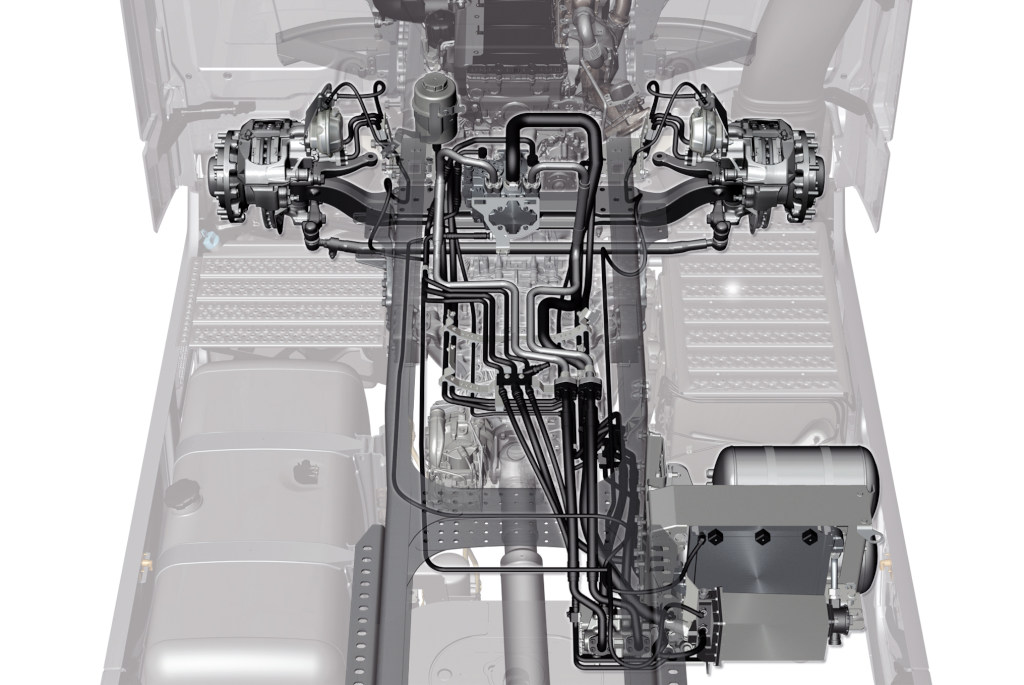

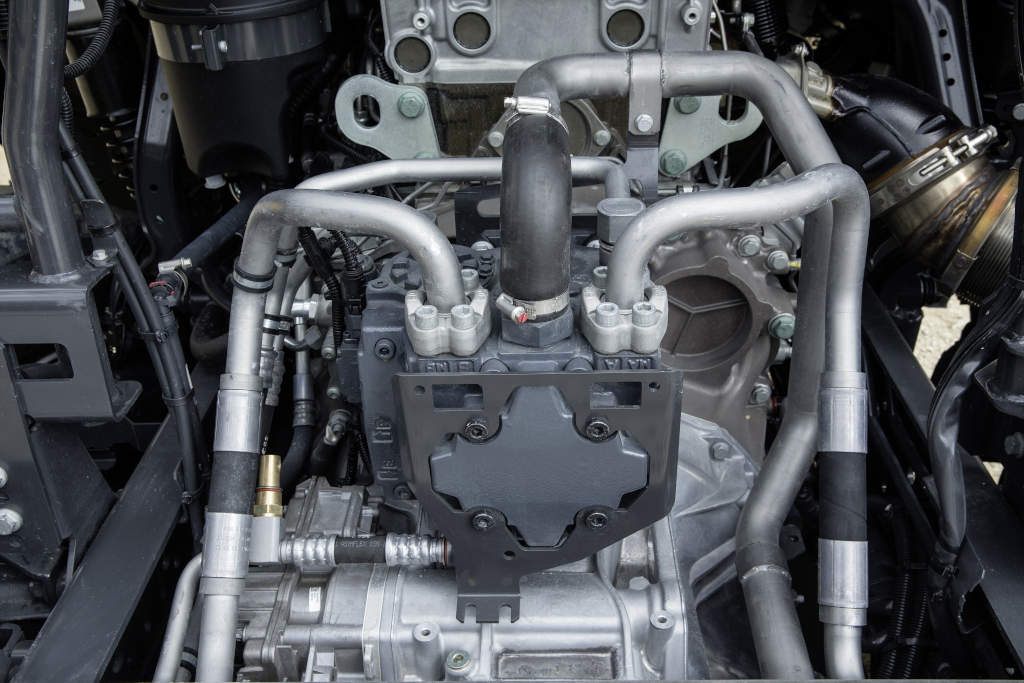

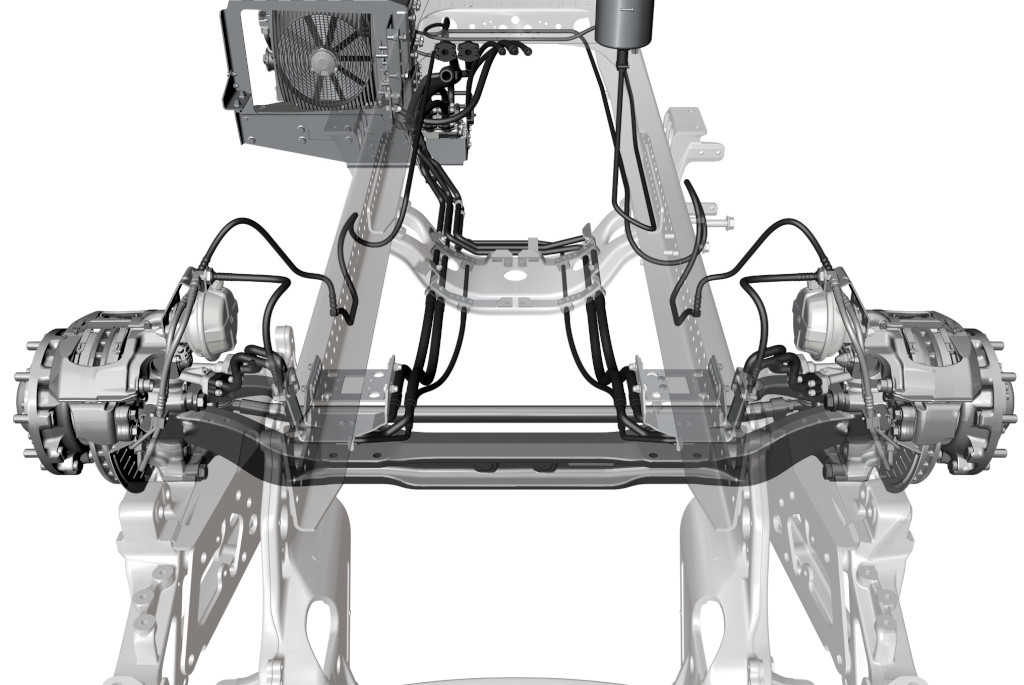

Oil lines run to the high-pressure pump mounted behind the engine. The pump has an output of up to 112 kW and delivers a flow rate of up to 350 litres of oil per minute at a maximum pressure of 450 bar.From here, high-pressure lines run to the hydraulic wheel hub motors in the front wheels – a quasi special additional drive system: on-demand, lightweight and fuel efficient. If you look behind the front wheels in the wheel wells, you see that the lines cannot twist when steering, thereby ensuring a long service life.

The abbreviation HAD stands for Hydraulic Auxiliary Drive, an additional drive system. It is only used when needed and its technology is very different from a classic mechanical all-wheel-drive system with transfer case, drive shaft, differential and half shafts on a permanently or on-demand driven front axle.

The wheel hub motors are supplied with hydraulic oil directly through the axle bolt and the axle journal. A rotary distributor in the axle stub protects the high-pressure hydraulic lines against twisting when steering. The system only has to compensate for the suspension motions and not for steering motions – a major plus in favour of a long service life.