7.9 L fuel/100 km with battery depleted (tested under customer’s operating conditions)

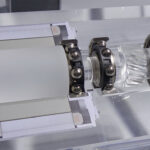

eAxle efficiency improved with three-bearing system integration, forced lubrication, fluid centrifugal force control, and software algorithm optimization reducing controller losses

High reliability and low NVH

Suitable for 4.5T to 10T models, with the reducer lifespan designed using the load spectra of 10T models, ensuring 10-year/800,000 km durability

Two rear axle ratios: 4.11 for low fuel consumption and 4.875 for heavy mountainous loads

Low energy consumption: 7.81 L/100 km (31.8 kWh/100 km) at the rear axle ratio of 4.11; 8.28 L/100 km (34.3 kWh/100 km) at the rear axle ratio of 4.875; about 10 L/100 km in 10T full-load and battery-depleted state

4.5T model hits 0-50 km/h in 5 s, 0-100 km/h in 18 s, with 35% to 40% gradient

Oil pump refined from 300 W to 200 W for specific needs

Parallel-axis single-speed DHT architecture, integrating dual inverters, dual motors, reducer, hydraulic control, and clutch

Maximum rated power of 140 kW achievable through series-parallel modes, with peak wheel-end torque of 5000 Nm to 10,000 Nm for diverse light truck loads