KIRCHHOFF Automotive

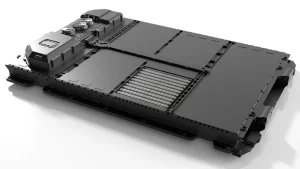

Lightweight battery housing made of steel and aluminum

Aluminum profiles form the outer frame

Steel bent tub with laser-welded corners

Joining of the aluminum outer frame with the steel tub by adhesive bonding

Economical concept in a hybrid design

Utilization of the respective material properties

High volume utilization

High structural performance

Process-optimized tray concept

Reduced joint seam lengths for simplified realization of tightness

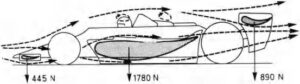

Lightweight battery housing made of aluminum

Aluminum profiles form the outer frame

Aluminum bent tub with laser-welded corners

Joining of the aluminum outer frame with the aluminum tub by adhesive bonding

Weight-optimized aluminum concept

High volume utilization

High structural performance

High corrosion resistance

Reduced joint seam lengths for simplified realization of tightness

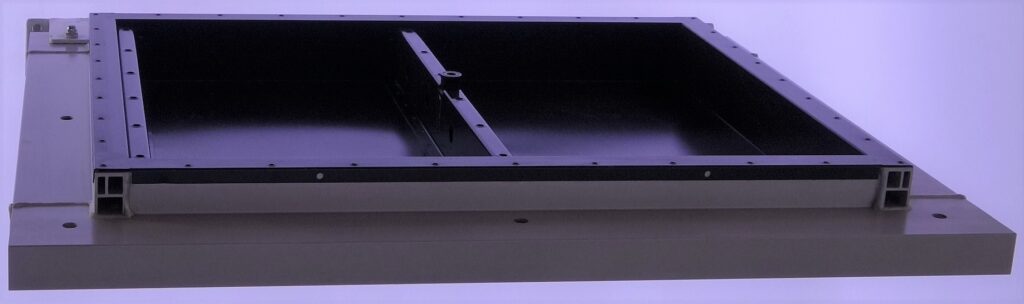

Lightweight battery housing with built-in tub concept

Aluminum profiles form the outer frame

Joining of the aluminum outer frame with the base plate by laser welding

Weight-optimized concept, optionally with integrated cooling function

High volume utilization

High structural performance

High corrosion resistance

Use of integrated cooling bottoms possible