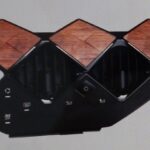

Composed of a limited number of modules instead of a large number of components, designed using sustainable materials, as a value-added alternative to today’s regular seat. The modules can be easily assembled and disassembled, allowing the parts of the seat to be replaced and new functions to be added throughout its lifetime, providing greater longevity and facilitating the recycling of its constituent parts.

This new approach to seating design drastically reduces the number of components used in a regular seat from around 120 components to 10 modules which can be assembled in a wide variety of configurations close to the car manufacturer. Another advantage of the modular seat architecture is that it can be adapted to any car manufacturer and seating frame platform, covering multiple vehicles with significantly reduced upfront costs.

Focused on sustainability, this approach is also reducing the carbon footprint of seating inspired by circularity: streamlining design to use less material; choosing sustainable materials that are recyclable, recycled or bio-sourced (including fossil-free steel); avoiding mixed materials to simplify recycling; making seats easier to assemble and disassemble; and concentrating the production of modules in regional centers to allow the seat to be assembled as close as possible to the customer’s site.

Longer vehicle product lifecycles and increased demand for onboard comfort have created the need for vehicle owners to be able to change some parts of the seat to extend the life of the vehicle, and to add new functions to the seat for a customized well-being experience.

Faurecia’s new modular and sustainable seat makes it easy to exchange or replace parts such as covers and cushions, or upgrade with innovative new features like massage, lumbar support, sensing, immersive sound experience and other comfort modules over the seat’s lifetime.

With the brand new modular and sustainable seat introduced at CES 2023, Faurecia is continuing its innovative seating design approach that is completely rethinking seats from frame to foam, covers and accessories. The first cars featuring this kind of seat should roll off the production lines in 2025.