Georg Fischer Automotive

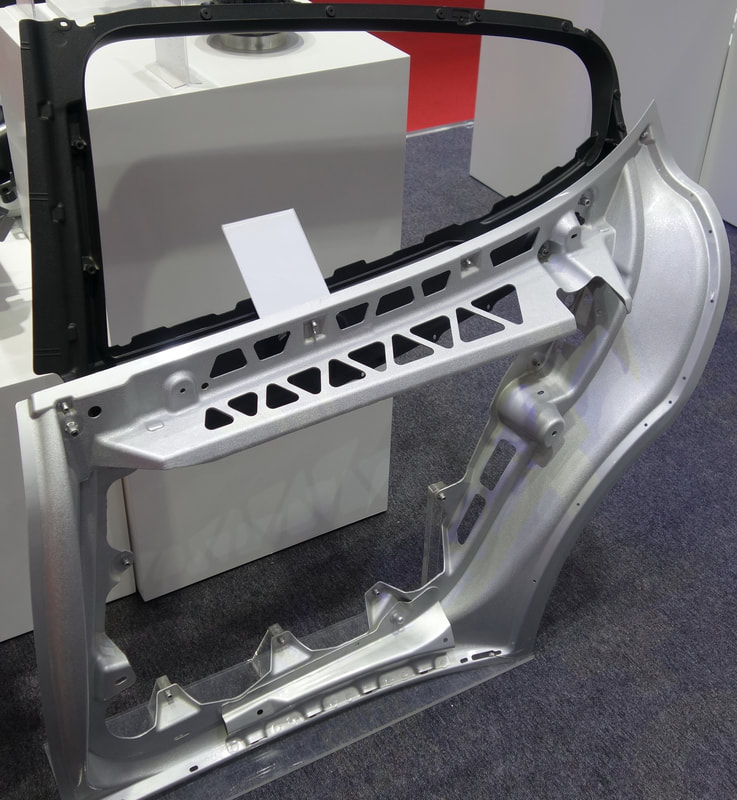

One door frame is made of the alloy AlMg 5Si2Mn. Among other things, a reinforcement plate is attached in the door-sill area by means of Deltaspot welding.

A further Georg Fischer innovation is the laser cutting process, which for the first time in the automotive industry determines the door frame’s precise outside geometry. This is intended to improve the appearance after the flanging process. These stipulations are complied with by the laser cutting process, since this improves the cant quality considerably compared to stamped castings.

Wall thicknesses of only 2.0 to 3.5 mm are a further characteristic of the door frames. For instance, with its weight of 3.6 kg, the rear door frame is about 30 % lighter than a comparable sheet-steel component.