Continental has presented a driverless and fully electric test vehicle which it has developed for measuring the braking performance of passenger car tires. The objective of the fully automated test is to further reduce the braking distance of tires to ensure greater road safety. The AVA – “Analytic Vehicle AIBA” – enables precise monitoring of the frictional properties of tires during braking maneuvers on dry and wet roads. For the first time, the Continental AVA combines the advantages of a test method which is independent of the vehicle model, with the controlled and reproducible test environment of the Automated Indoor Braking Analyzer (AIBA).

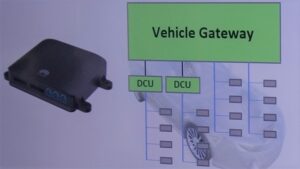

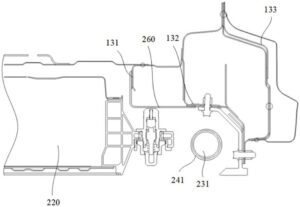

For the tire braking tests, the AVA is accelerated to a test speed of 65 km/h with the aid of an electromagnetic linear drive, which is derived from modern roller coaster technology. Then, several fully automated braking tests are carried out. The AVA drive system is equipped with two electrically driven axles, which are powered by a high-performance battery. The high maximum torque ensures that a constant speed can be maintained, while the test tires on the third axle can be systematically braked. The integrated braking system of the AVA is equipped with Brake-by-Wire technology from Continental’s Automotive business sector. Unlike conventional hydraulic braking systems, the braking signal is transferred electronically. The brake response is very quick and precise, which is essential for accurate testing or measuring.

“Our AVA determines the transmission of forces between the tire and the road surface, while various slipping states, so-called “µ-slip curves”, are precisely reproducible. With the state-of-the-art measuring technology we measure all of the forces which act between the tire and the road surface during braking. We can compare our tires and their various compound compositions even more precisely and optimize them for their special uses,” explains Meletis Xigakis, who is responsible for global tire testing at Continental.