The BMW Group is launching a unique project that will see cars manoeuvre around production without requiring a driver. The Automated Driving In-Plant project (‘Automatisiertes Fahren im Werk’, AFW) is being realised in collaboration with two startups and will enhance the efficiency of new-vehicle logistics in plants and distribution centres.

The aim of the AFW pilot project is for vehicles to move autonomously around logistics areas and assembly – safely, efficiently and without requiring a driver. To make this happen, the BMW Group has been collaborating with Seoul Robotics from South Korea and Embotech from Switzerland. Launching in July 2022 at BMW Group Plant Dingolfing, the new system will first be trialled on two cars: the new BMW 7 Series and the fully electric BMW i7.

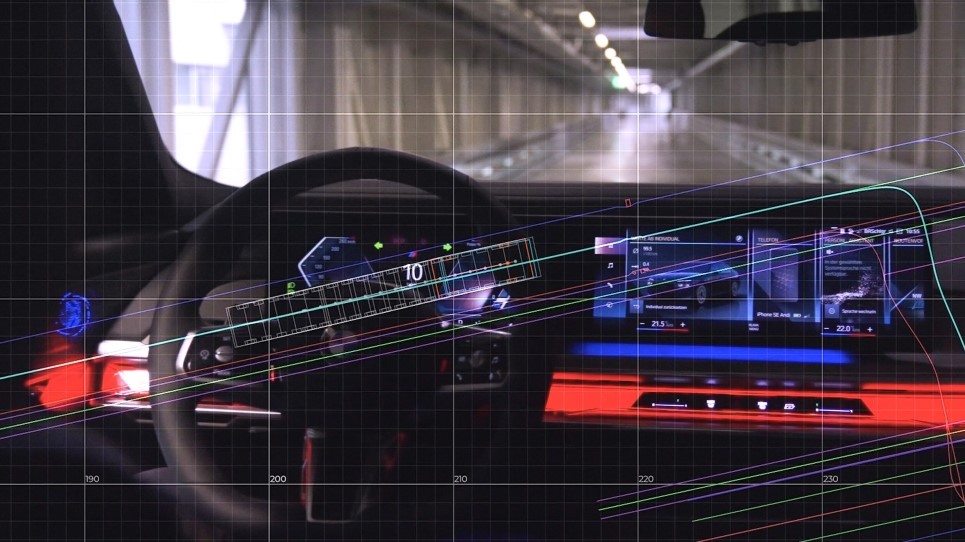

“Automated driving within the plant is fundamentally different from autonomous driving for customers. It doesn’t use sensors in the vehicle. In fact, the car itself is more or less blind and the sensors for manoeuvring them are integrated along the route through the plant,” explains BMW Group project manager Sascha Andree. AFW builds on two key technologies: a sensor infrastructure to support vehicle localisation and detect obstacles in the plant environment, and a drive-planning software that transmits controlled commands to the driverless vehicles via mobile communications.

Initially, the vehicles will only move through the assembly area and then to logistics. Fresh off the production line, they will drive themselves to a parking area, ready for their onward journey by train or truck. Essentially, the technology can be used from the moment the cars are capable of driving independently in production – just after the first ignition of the engine, in other words.

Seoul Robotics’s lidar detection software uses static monitoring sensors to create a digital twin of the environment, including object classification and vehicle localisation, while Embotech’s drive-planning software steers, brakes, accelerates and parks the driverless vehicles. Routes are calculated in real-time, and rather than needing to be trained or programmed for the current situation, each car is able to respond independently to its surroundings.

The pilot project will run for several months. Later it will be rolled out further, initially on additional models at Plant Dingolfing and later in other plants as well.