The Audi Q6 e‑tron is the first model series based on the completely redeveloped Premium Platform Electric (PPE) and the new E3 electronics architecture.

The 800-volt architecture, which is required for charging outputs of up to 270 kW, is one of the key factors for high charging performance.

Due to the 800-volt architecture, thinner wire can also be used for the wiring of the battery and the electric motor. This reduces installation space, weight and consumption of raw materials. Because the system heats up less due to lower heat loss, the cooling system is also smaller and more efficient.

With a state of charge (SoC) of about ten percent, vehicles in the Audi Q6 e-tron series need just ten minutes at a fast-charging station at a maximum charging power of 270 kW with DC charging to generate a range of up to 255 kilometers (158 miles) under ideal conditions. It takes 21 minutes for the HV battery to be charged from an SoC of ten percent to 80 percent. A communications control unit, referred to as the Smart Actuator Charging Interface Device (SACID), acts as an interface to establish a link between the charging socket and the charging station and transmits the incoming standardized information to the HCP5 domain computer.

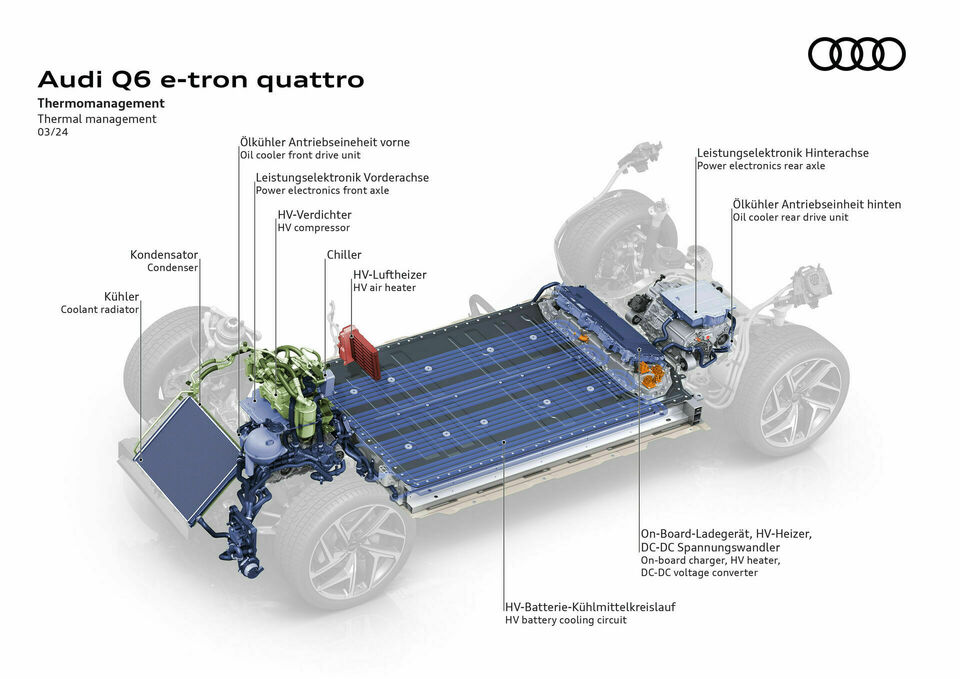

In addition to the 800-volt architecture, intelligent thermal management makes a significant contribution to high charging performance and the long service life of the HV battery in the PPE. The most important component is predictive thermal management, which uses data from the navigation system, the route, the departure timer and the customer’s usage behavior to calculate the need for cooling or heating in advance and to provide them both efficiently and at the right time.

Post and continuous conditioning is another new feature in the PPE’s thermal management system. This function monitors the battery temperature for the entire service life to keep the battery at the optimum temperature range even when the vehicle is stationary – for example, at very high outside temperatures. The coolant flow was optimized by implementing the U-flow principle underneath the battery modules. This leads to high-temperature homogeneity within the battery – monitored by 48 temperature sensors – and ultimately to high energy delivery and absorption performance.

The vehicle’s thermal management system has been redesigned. To compensate for the increased efficiency in the drivetrain and the resulting reduction in heat loss, the water-glycol heat pump is supplemented by an air heat pump. This means that in addition to the waste heat in the coolant of the electric motor, power electronics, and battery, the ambient air can also be used as a heating source for the interior. The temperature exchange now works directly via a heating coil. Moreover, an 800-volt air PTC heater was developed as an effective addition, which also directly supports the interior temperature control in the air conditioning unit in the event of increased heating requirements. This avoids the heat losses associated with water-based heating circuits.

whats hilarious to me is hearing thesears running fans in the summer as they park outside.

using the battery’s power, to keep the temperatures down, whilst just sitting there in a hot parking lot…

AND THEN!

to hear them run pumps (and i am guessing a heater) to keep the batteries at elevated temperatures in the winter…

so then realize, most of the world is using natural gas and coal to keep these things charged.

JUST SO THEY CAN MAINTAIN SOME NOMINAL BATTERY TEMPERATURE.

that is, to use energy to simply exist.

(until the batteries fall below usable charge, then its off to the battery graveyard)

every year. i inspect the spark plug on my lawn mower. and pour some gasoline in it (unknown quality or age)

and it immediately runs. i have been doing this for some decades now.

what energy was utilized in the storage of that fuel???

it is the same for my diesel vehicles.

you all are being scammed by this non-sense.

its like all those wind-turbine blades being buried and some of them have diesel generators (generating electricity, inside them)