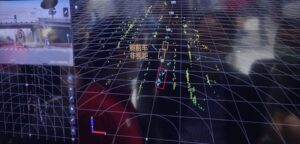

Of particular importance as a basis for new vehicle development is the powertrain with its corresponding electronic control units (ECUs). To develop and validate the powertrain, Toyota has strongly promoted the introduction of model-based development (MBD) and relies on the early use of simulation in the development process. At Toyota, software-in-the-loop (SIL) simulation is performed with VEOS, the PC-based simulation platform from dSPACE for process improvement, enabling the integration of virtual ECUs created with dSPACE’s SystemDesk software into a variety of plant models. Through SIL simulation, developers gain early insight into the powertrain and especially the relevant ECU software, which they can then use directly to develop and improve algorithms and entire systems. Developers at Toyota have reported shorter test cycles and more reproducible verification of results. Hirotaka Kaneko, who is responsible for powertrain test environment at Toyota Motor Corporation, reports, “With VEOS, we were able to benefit from a reliable software simulation platform from dSPACE for the validation of new powertrain controls and to front-load the control software development.”

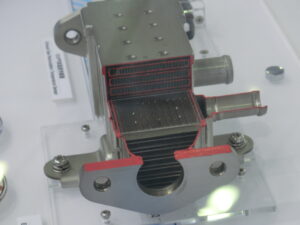

For the subsequent hardware-in-the-loop (HIL) simulation, forming a tool chain with dSPACE SCLAEXIO enables the seamless use of test scenarios, parameterized models, and other results from SIL to HIL, reducing the effort required for verification and validation of production-ready ECUs. Toyota Motor Corporation has created a development platform that enables efficient evaluation of control software and ECU hardware by standardizing various tests, including automation, using SIL and HIL simulation platforms from dSPACE.